1.This equipment is suitable for rolling steel cylinders.

2.The rolling modes include forward rolling and reverse rolling.

3.Place the steel cylinder upright on the equipment first, and then start the rolling after it is turned over and lies flat.

4.The turning of the steel cylinder is controlled by an air cylinder.

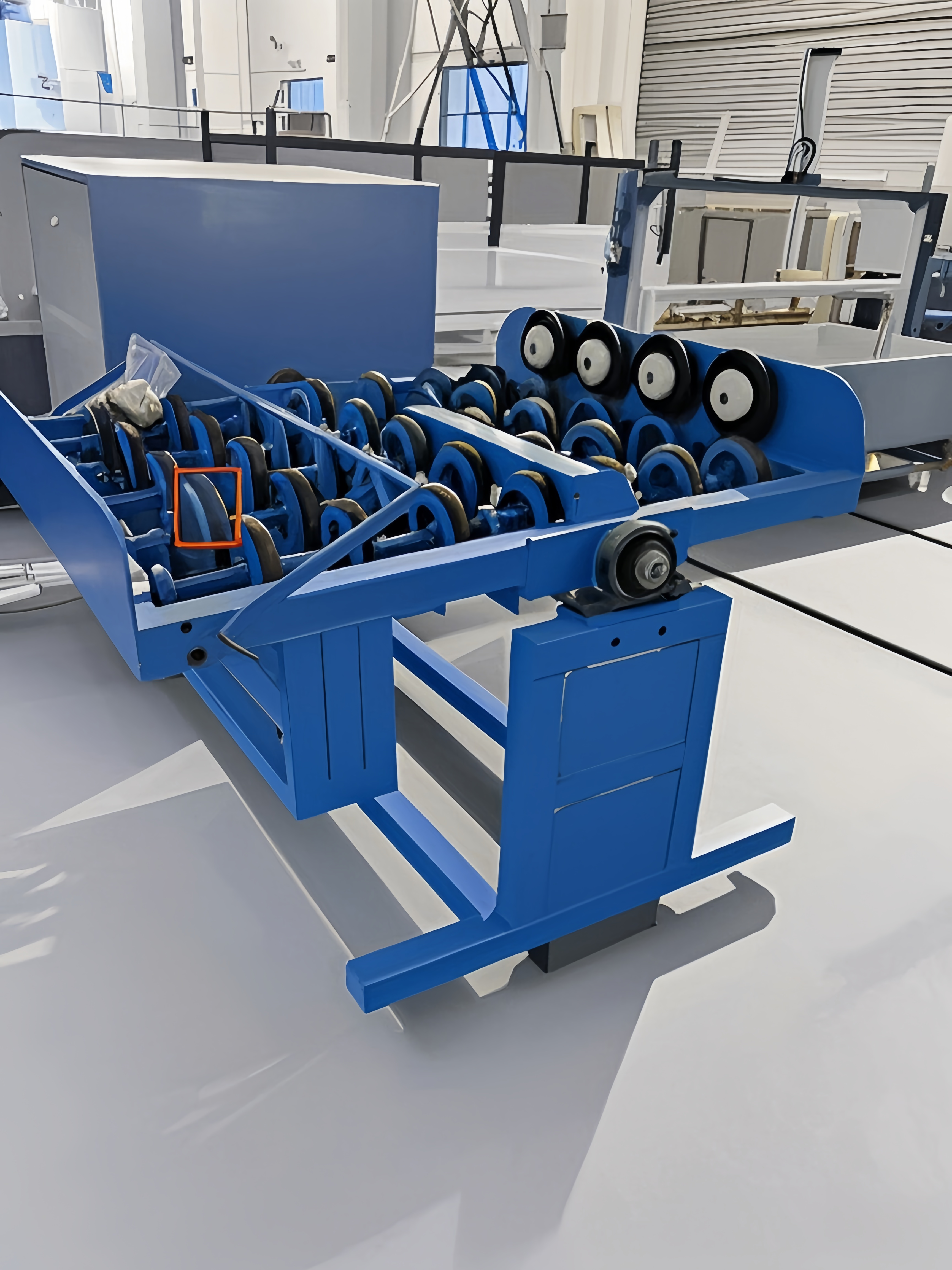

5.Rollable bottle supports are installed on the rolling bottle base plate.

6.The part where the steel cylinder contacts the rollers is protected by polyurethane material to prevent damage to the surface of the cylinder body.

7.A bracket to prevent the steel cylinder from falling is installed on the turning frame. When setting the protective frame, it should be considered that it can be easily opened and closed by workers during the process of loading and unloading the cylinders.

8.An emergency stop button is provided on the electrical panel.

9.It can meet the specifications of gas cylinders: the outer diameter is not more than 250mm, and the height is not more than 1700mm (40L – 60L).

10.The maximum number of cylinders that can be rolled at one time is 4.

11.The equipment has a timing operation function, and the setting time ranges from 0 to 2 hours.

成为第一个“Gas Cylinder Rolling Machine Cylinder Rolling and Rust Removal” 的评价者 取消回复

Applicable Cylinder Diameter: Φ150 – 250mm

Number of Cylinders Rolled Each Time: 4 pieces

Roller Rotation Speed: 94.2 r/min

Tilt Angle When the Turning Frame is Horizontal: 1 – 5° with the bottom of the cylinder downward

Tilt Angle When the Turning Frame is Vertical: 10 – 20° (tilting backward when vertical)

Working Power Supply: AC380V/50HZ

Protection: Anti-collision brackets are installed on the front.

Electrical and Control (Explosion-proof Requirements): ExⅡB T4

评价

目前还没有评价