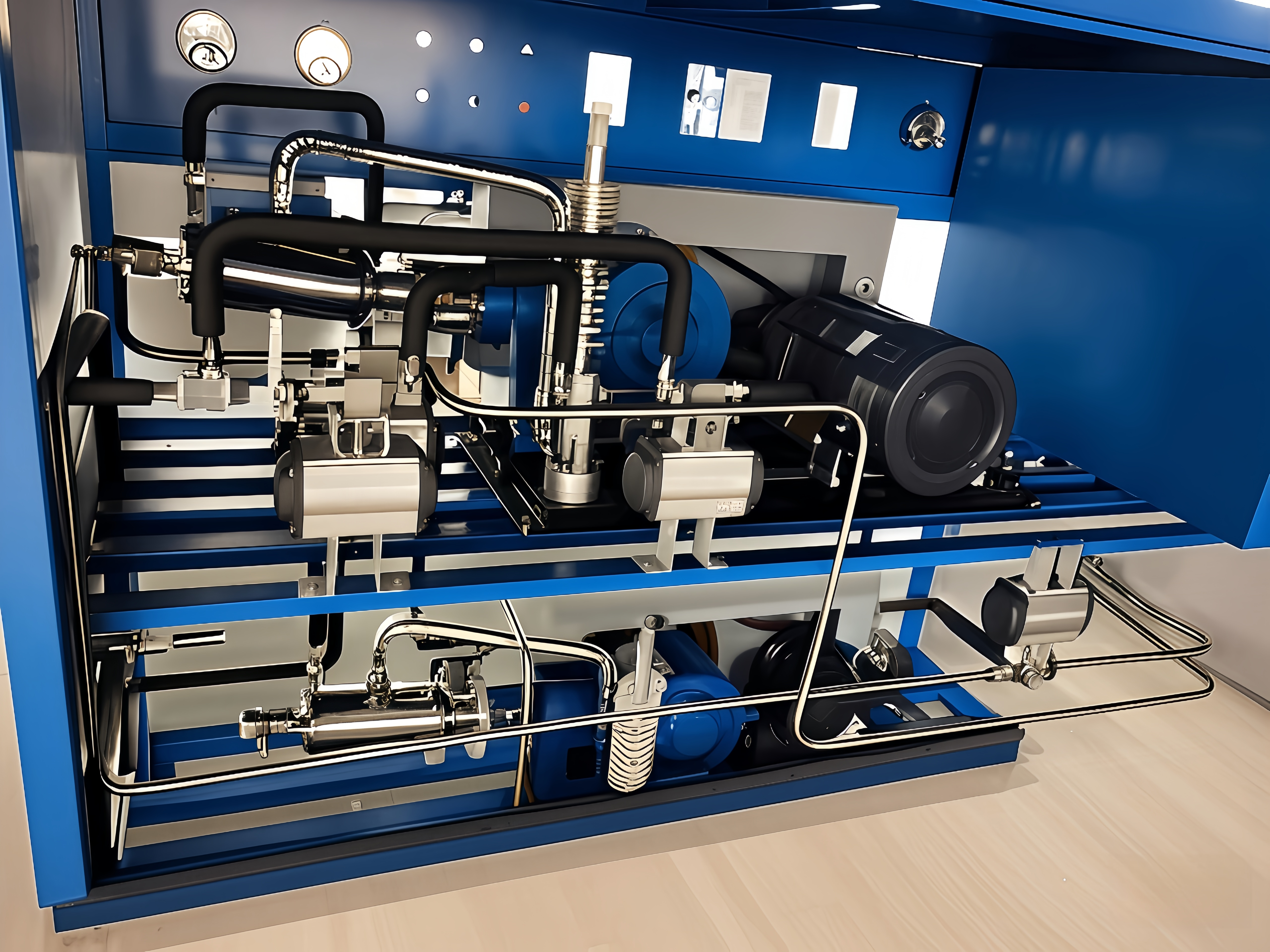

The test device is composed of parts such as a control cabinet, a water quantity collection and pressurization system, a pressure test water jacket, and a weighing electronic scale (optional).

The control software of the test device adopts the LabView industrial control software. The computer is responsible for weighing the gas cylinders, setting the parameters for the hydraulic pressure test, printing the hydraulic pressure test reports, and viewing the results of the hydraulic pressure test.

The designed maximum working pressure of the test device is 51 Mpa. The control accuracy of the actual test pressure is not lower than 50 Psig, and the actual water level measurement accuracy is not lower than 0.1 g. When the test device is in operation, it has a high degree of operation automation. After inputting the serial number of the test gas cylinder, it only takes a few key presses to complete the process from weighing to finishing the hydraulic pressure test under normal circumstances. During the test, the relationship curves of time/pressure, time/water quantity, pressure/water quantity during the test process can be dynamically displayed in a graphical manner. The test device saves all the data of the test process, and users can view all the test data and various test curves of the tested gas cylinders whenever needed.

The control software of the test device adopts the LabView industrial control software. The computer is responsible for weighing the gas cylinders, setting the parameters for the hydraulic pressure test, printing the hydraulic pressure test reports, and viewing the results of the hydraulic pressure test.

The designed maximum working pressure of the test device is 51 Mpa. The control accuracy of the actual test pressure is not lower than 50 Psig, and the actual water level measurement accuracy is not lower than 0.1 g. When the test device is in operation, it has a high degree of operation automation. After inputting the serial number of the test gas cylinder, it only takes a few key presses to complete the process from weighing to finishing the hydraulic pressure test under normal circumstances. During the test, the relationship curves of time/pressure, time/water quantity, pressure/water quantity during the test process can be dynamically displayed in a graphical manner. The test device saves all the data of the test process, and users can view all the test data and various test curves of the tested gas cylinders whenever needed.

评价

目前还没有评价