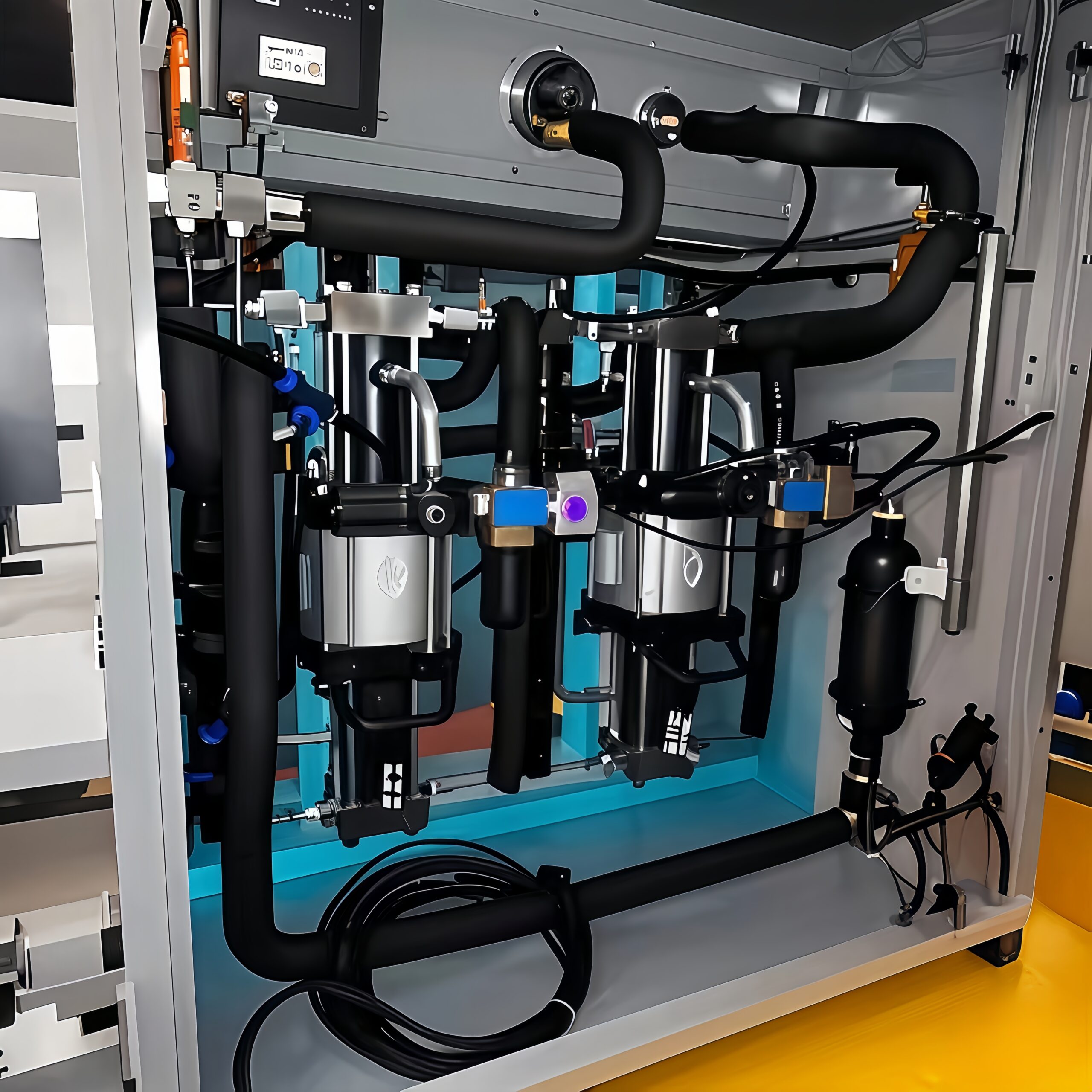

The filling system uses compressed air as the power source. Through the pneumatic booster pump, the agent is driven to be transported and filled at high pressure in a proportional and automatically reversing reciprocating pressurization manner, greatly improving the filling speed. The electronic scale can set the filling weight. When the delivery flow reaches the set value, a signal is sent to the filling high-pressure pneumatic ball valve through the flowmeter, and the valve is automatically closed to stop the filling. For vacuuming, a 1L/S large-flow vacuum pump is used to quickly achieve vacuum in the filling bottle, improving the filling speed and the purity of the agent. When filling with nitrogen, first reduce the pressure to the required pressure through the pressure reducing valve to improve the filling stability and prevent overshoot. Open the nitrogen valve to inject nitrogen. Observe the pressure gauge. When the set pressure is reached, close the nitrogen valve, and the entire filling process is completed.

Warning: Trying to access array offset on value of type bool in /www/wwwroot/unitychy.com/wp-content/plugins/woocommerce/includes/wc-template-functions.php on line 1727

Warning: Trying to access array offset on value of type bool in /www/wwwroot/unitychy.com/wp-content/plugins/woocommerce/includes/wc-template-functions.php on line 1728

Warning: Trying to access array offset on value of type bool in /www/wwwroot/unitychy.com/wp-content/plugins/woocommerce/includes/wc-template-functions.php on line 1729

Warning: Trying to access array offset on value of type bool in /www/wwwroot/unitychy.com/wp-content/plugins/woocommerce/includes/wc-template-functions.php on line 1730

Warning: Trying to access array offset on value of type bool in /www/wwwroot/unitychy.com/wp-content/plugins/woocommerce/includes/wc-template-functions.php on line 1750

Warning: Trying to access array offset on value of type bool in /www/wwwroot/unitychy.com/wp-content/plugins/woocommerce/includes/wc-template-functions.php on line 1750

评价

目前还没有评价